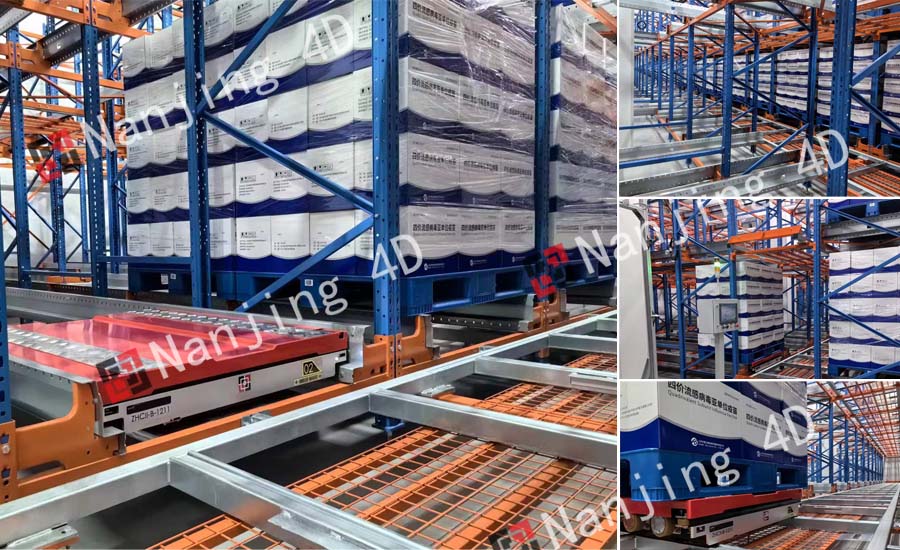

A 4-Way Shuttle Project in Taizhou

Congratulations on the successful completion of the four-way shuttle automated warehouse project of a pharmaceutical industry in Taizhou, Jiangsu Province in mid-April.

The pharmaceutical company cooperating in this project is located in Taizhou Pharmaceutical High-tech Zone. It is a large integrated pharmaceutical company engaging in scientific research, production, technology and import and export trade. This project is used to store 2-8℃ vaccines. The vaccines are various, most of which are outbound through picking. The efficiency requirement is not high.

Implementation difficulties: The implementation time required by the project is too short, which is about 2 months. Meanwhile, multiple parties participate in the construction together.

Technical highlights: This is the first automated high density warehouse project for vaccine bank in China. Through the organic cooperation between the four-way intensive Warehouse Management System (WMS), Warehouse Scheduling System (WCS) and the automatic control system, it can realize the automatic execution of vaccine import and export operations, accurate positioning of inventory location, monitoring of inventory status in real time and inventory information updating in real time. The project promotes the whole process of digital cooperative management of sales, production, warehousing, quality inspection, delivery and other operations.

Industry level: The four-way high density warehouse for pharmaceutical industry can realize the flexible division of single storage space and multi-depth of racks, reducing laneway area and equipment investment. The space utilization rate can reach 3-5 times of the traditional flat warehouse, saving 60% to 80% of labor and improving the working efficiency by more than 30%. It not only greatly reduces the area of pharmaceutical warehouse, improves the accuracy and turnover efficiency of logistics operations in pharmaceutical enterprises" warehousing, but also effectively reduces the error rate of drug delivery and the comprehensive production cost of the enterprises. The safety of drug storage is also well guaranteed under the premise of ensuring storage density.

The implementation of this project has been highly recognized and praised by customers. Both of us are looking forward to more extensive cooperation in the future.