The conveyor system is customized and designed by our company and produced by outsourcing, with strong compatibility and stable capacity, coupled with professional and mature program design, the entire process of conveying cargos is safe and reliable, and the data transmission is also accurate and controllable, which can meet the needs of various scenarios. There are mainly the following classifications: chain conveyor, roller conveyor, transfer conveyor.

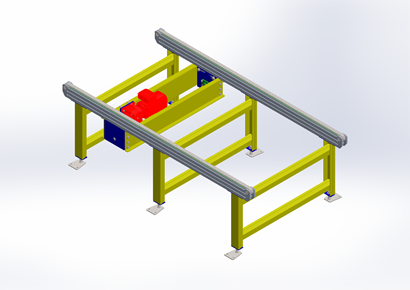

1. Chain type conveyor

The chain conveyor is driven by a geared motor, the motor is installed on a preset pedestal, the chain rolls on section steel, constitutes a whole with the structure of the conveyor and is positioned under the chain; the motor reducer rotates at a pre-designed speed by sprocket and chain, thereby driving the tray cargos on the chain to move, so as to achieve the purpose of conveying the tray cargos.

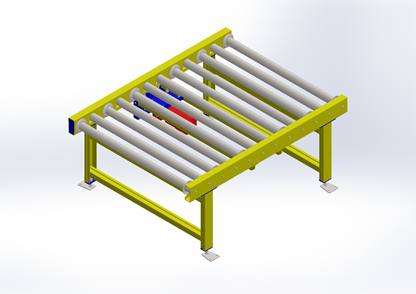

2. Roller type conveyor

The powered roller conveyor is composed of the powered roller module, the aluminum veneer, the card-frame, the pull rod, the bearing seat, the driving device and the chain. The non-powered roller is composed of non-powered roller module, the aluminum veneer, the card-frame, the pull rod and the bearing seat. The powered roller rotates to conveys cargos because the driving device drives the drag-chain, and the chain drives the sprocket on each powered roller. The non-powered roller conveys things freely by pushing and pulling workpieces by people or squeezing between workpieces.

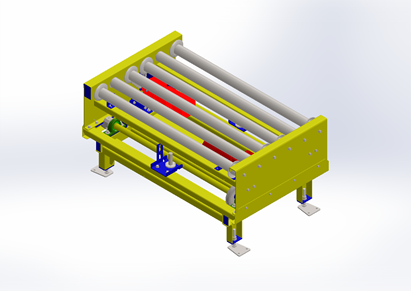

3. Transfer conveyor

The lifting transfer conveyor is generally used to change the conveying direction of the cargos, and move the cargos into or out of the main conveying line from the minor line. It has the characteristics of large load, simple structure, stability and reliability. The equipment adopts PLC programmable control, so that cargos can easily enter and exit the main and minor conveying lines without collision, extrusion and other phenomena. The lifting transfer conveyor we developed adopts four fulcrums for balanced lifting. Even if cargos are not placed correctly and the side or corner of the equipment is stressed, the conveyor can still be lifted smoothly without blocking or jamming. And the main advantage is the right-angle turn: the conveyor can realize right-angle turns under the condition of limited space which could save space.